Engine Blocks Can Be Manufactured Using Which Methods

Engine blocks can be manufactured using which methods. Engine blocks can be manufactured using which of these methods.

How It S Made Engine Blocks Youtube

Without researching the market conditions Fresnas Inc.

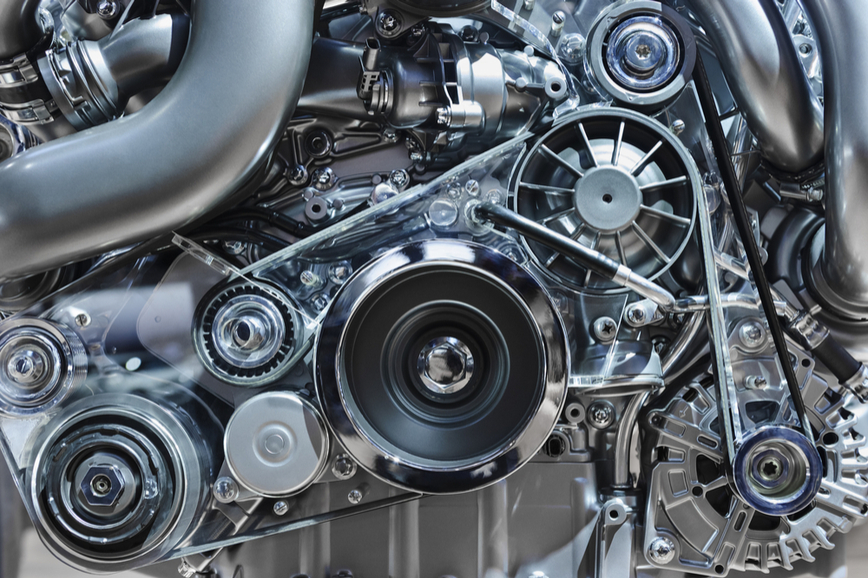

. Improvements can be achieved with a properly designed oil pan often designed as an aluminium casting. Sand casting die casting and lost-foam casting. The stiffness of the engine block can be increased for example by using a short-.

Finally the machining cost is around 60 AUD per hour. Engine blocks are normally cast from either a cast iron or an aluminium alloy. There are methods to cast forms such as engine blocks with internal passages for coolant oil etc.

If stiffness is the most important characteristic of the engine block two-element designs are preferred. A Sand cast B Die cast C Extruded cylinder D Machined from a solid piece of metal. The aluminium block is much lighter in weight and has better heat transfer to the coolant but iron blocks retain some advantages such as durability and better clearances from heat expansion.

A Sand cast or die-cast B Extruded cylinder C Sand cast D Machined from a solid. There are several different types of manufacturing processes to choose from out there and many different alloys that are at ones disposal to be used. Engine blocks can be manufactured using which of these methods.

Engine block and unsatisfactory acoustic characteristics. The host using a completely torn-down engine block from a 2001 Miata talks you through 18 straight minutes of how the piece is formed what materials are used and all the intricate details that. Technician B stated that the lubricating passages in an engine block are called the oil gallery.

The metal is heated to 800 degrees C and then poured into a sand mold where it hardens and sets. Technician A says that engine blocks are either cast iron or aluminum. It hopes that customers will like its new product.

Engine blocks were traditionally made from cast iron but in the interest of better fuel mileage lighter aluminum alloys have been introduced. Up until the early 90s many Japanese OEMs looked to cast- iron blocks for forced-induction performance applications. Chemical formula respectively of these alloys has the form AlSi8Cu3 and AlSi6Cu4.

Tap the main galleries at the front of the block so that pipe plugs can be installed. A number of legendary engines featured cast iron blocks. Engine blocks can be manufactured using which of the methods.

Machine the deck for straightness and proper surface finish. Engine blocks can be manufactured using which methods. Engine blocks can be manufactured using which of these methods.

Chase clean-up the threads in all tapped holes. Align hone or align bore the main caps and saddle. Went ahead and manufactured windshields with the new glass.

Ultrasonic testing is used to test _____. Many late model Ford GM Chrysler and import blocks have cast-in-place iron sleeves but some European makes have plasma sprayed cylinder coatings. Technician B says that cores are used inside a mold to form water jackets and cylinder bores.

Instead of using a resurfacing machine a boring machine a milling machine and a range of specialty fixtures all block work with the exception of final cylinder honing and main bore align honing if needed can be accomplished on one machining center and in far less time that it takes using traditional methods. Researchers at Fresnas Inc. Cast iron - Gray cast iron Gray cast iron alloy have been the dominant metal that was used to manufacture conventional gas-powered engine blocks Gray cast iron alloys typically contains 25-4 wt carbon 6 and 1-3 wt silicon 02-10 wt manganese 002-025 wt sulfur and 002-10 wt phosphorus ADVANTAGE It has excellent damping capacity good wear and.

After the engine block has been machined. Invented a new form of glass that filters harmful rays of sunlight and blocks heat. I like o-rings in the block because the heads can warp a little and be easily milled flat during freshen-ups without pulling the ring out he said.

Align honing block decking cylinder boring. Toyotas 2JZ Nissans RB26 and Mitsubishis 4G63. Either the block or the head can be machined for the ring or the receiver groove and Bacalis said he uses a different installation method for O-rings than he does for fire-rings.

For the performance engine. Sand Casting The sand molds used to cast engine metal can be used only once. Which of the following statements about this scenario is true.

Before the advent of alloy engine blocks cylinders were cast-in features of the cast-iron engine block. The production of cast iron blocks using a steel die is rear because its lifecycle is shortened as a result of the repeated heat cycles caused by the molten iron. Sand Cast or Die Cast.

As for aftermarket aluminum blocks its mostly press fit cast iron ductile. In this report sand and die casting will be discussed with the focus on sand casting. The cost of the manufacturing process for a foundryman in case of sand casting is around 45 AUD per hour and if there is a mass production of engine blocks the use of aluminium die casting can be implemented being slightly more expensive with the tools required.

Sand cast or die cast. Sand casting is the method widely used in the production of cast iron blocks. A bedplate is located between the _____ and the _____.

Casting aluminum alloys which are used for the manufacture of car engine blocks usually include alloys 46200 and 45000 of European Standard EN 1706 bulky prefix EN AC- omitted. Sand cast or die-cast. An engine block should be machined in which order.

Engine blocks can be manufactured using which method. Their American counterparts - better known - are A3802 and A319 alloys. Sand cast or die cast.

If memory serves me right I think one of the processes is called the lost wax method where the pattern is built-up of a meltable material the mold is formed using sand around the meltable material then the mold is heated to remove the pattern leaving an internal. Hone the lifter bores. The idea that a print is made from a matrix has been altered by the use of an.

Remove all burrs and casting slag from block interior.

Aluminum Casting For The Engine Industry Leclaire

Engine Blocks Aluminum Vs Iron Youtube

Engine Block Manufacturing Process Cylinder Block Green Sand Molding Lost Foam Process Esm Youtube

Comments

Post a Comment